Medical extrusion is a crucial process in the manufacturing of medical components, providing the precision and reliability necessary for medical devices and equipment. Through extrusion, manufacturers create custom profiles and components from a variety of materials, including plastics, rubber, and silicone. These materials are formed into specific shapes, sizes, and structures that meet the exacting standards of the medical industry.

The demand for high-quality, reliable medical parts is growing, with the advancement of technology in healthcare and the increasing complexity of medical devices. Services like MedSEA Forte – Precision Medical Tubing Extrusion are particularly valuable in producing components such as catheters, tubes, and seals, which are integral to modern medical devices.

In this article, we will explore the medical extrusion services available, their applications, and how these services help to create precision components for the healthcare industry.

What is Medical Extrusion?

Medical extrusion involves the process of forcing raw materials through a mold or die to create a specific shape or profile. This process is commonly used in the production of medical tubing, catheter shafts, and various flexible parts required for medical applications. The extrusion process can be tailored to meet the unique demands of the medical industry, ensuring that the components meet rigorous standards for performance, safety, and quality.

Materials used in medical extrusion must be biocompatible, as they come into direct contact with the human body. Common materials include thermoplastics, elastomers, and medical-grade silicone. These materials are carefully selected for their durability, flexibility, and non-reactivity, making them ideal for use in medical devices and treatments.

Applications of Medical Extrusion Services

Medical extrusion is used in various medical applications, where precision and reliability are paramount. The following are some of the most common uses for extrusion services in the medical field:

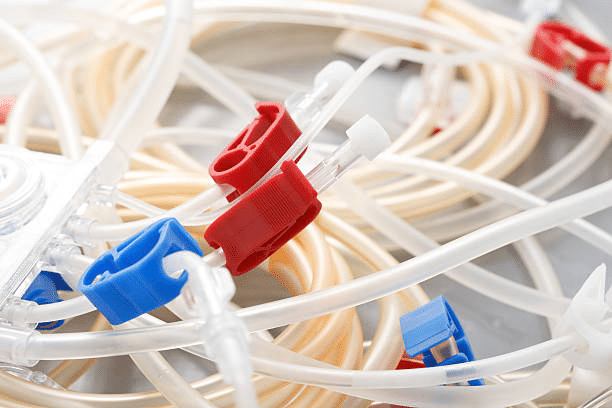

- Medical Tubing: One of the most common applications of extrusion in the medical industry is the production of medical tubing. Medical tubing is used in a wide range of devices, such as catheters, IV lines, and respiratory tubes. The extrusion process ensures that the tubing is manufactured to precise specifications, ensuring that it functions safely and effectively.

- Catheters: Extruded catheter shafts are essential in procedures such as minimally invasive surgery, diagnostic procedures, and the delivery of fluids or drugs within the body. The extrusion process enables manufacturers to create flexible, durable, and precise catheter shafts tailored to specific medical needs.

- Seals and Gaskets: Extruded seals and gaskets are used in medical equipment to prevent contamination and ensure that devices maintain a sterile environment. These components must be manufactured with high precision to ensure that they fit perfectly and provide the necessary protection.

- Profiles for Medical Devices: Extrusion is also used to produce custom profiles for medical devices. These profiles can be used in various medical applications, such as structural supports in surgical instruments or guides for specific medical procedures.

Advantages of Medical Extrusion Services

Medical extrusion offers several advantages when compared to other manufacturing methods, particularly when it comes to producing custom medical components:

- Precision and Customization: The extrusion process allows manufacturers to create components with highly specific dimensions, shapes, and properties. This level of precision is essential in the medical industry, where even small variations in size can have a significant impact on the performance and safety of a device.

- Cost-Effective: When large quantities of identical components are required, medical extrusion is an efficient and cost-effective manufacturing method. It enables high production rates without compromising on quality, making it ideal for medical companies that need to produce large volumes of components.

- Material Flexibility: Extrusion services offer a wide range of materials that can be used to manufacture medical components. These materials can be selected based on their specific properties, such as flexibility, durability, and biocompatibility, making them suitable for different medical applications.

- Consistency: One of the key benefits of extrusion is the ability to produce consistent, high-quality components. The continuous nature of the extrusion process ensures that each component is identical to the last, reducing the risk of defects and ensuring product reliability.

- Minimal Waste: Extrusion produces minimal waste compared to other manufacturing methods. This makes it an environmentally friendly option, as it reduces the amount of material lost during production and helps to maintain cost-efficiency.

Choosing a Reliable Medical Extrusion Service Provider

When selecting a medical extrusion service provider, there are several factors to consider to ensure that you receive high-quality and reliable components:

- Experience and Expertise: Look for a provider with extensive experience in the medical industry. A company with a proven track record in medical extrusion will have the knowledge and expertise to deliver high-quality components that meet the stringent regulatory standards of the healthcare sector.

- Certifications: Ensure that the extrusion service provider is certified in compliance with industry standards, such as ISO 13485, which ensures that the company follows best practices in medical device manufacturing. Certification demonstrates that the provider is committed to maintaining high-quality standards in their manufacturing processes.

- Customization Capabilities: Choose a provider that offers the ability to customize components to meet your exact specifications. Whether you need custom profiles, specific materials, or unique shapes, it’s important to select a provider that can meet your unique requirements.

- Quality Control: Quality control is critical in the medical industry. Make sure the extrusion service provider follows stringent quality assurance procedures to ensure that all components are manufactured to the highest standards. This includes testing for material properties, dimensional accuracy, and biocompatibility.

- Customer Support and Collaboration: The ability to collaborate effectively with your extrusion service provider is crucial for the success of your project. Choose a provider that offers excellent customer support and is willing to work closely with you to meet your specific needs and deadlines.

Conclusion

Medical extrusion services play a vital role in the creation of custom medical components, providing precision and reliability for a wide range of applications. From medical tubing and catheters to seals and gaskets, extrusion offers a cost-effective and highly customizable solution for the medical industry.

By choosing a reliable medical extrusion service provider, you can ensure that your components meet the highest standards of quality, performance, and safety. With the right extrusion services, manufacturers can create innovative medical devices that improve patient care and enhance the effectiveness of medical treatments.